News

News

Recently, Professor Weizhong Guo’s team from the Institute of Advanced Equipment Design and Control Engineering at the School of Mechanical Engineering, Shanghai Jiao Tong University, published a research paper in the international journal Mechanism and Machine Theory, titled 'A complete approach for error modeling based on failure of geometrical constraint and kinematic error node (KEN)'. In this work, the team is the first to propose a novel error generation mechanism based on the failure of geometric constraints in kinematic pairs, and introduce the new concept of Kinematic Error Node (KEN). Building on this foundation, they established a theoretically complete method for mechanism error modeling. This approach decouples the analysis of motion error from the physical cause of the error, enabling the construction of mechanism error models directly from error sources rather than relying on the differential of kinematic models. This advancement not only promotes the development of mechanism error modeling theory but also provides a new pathway for integrating precision considerations into the early stages of mechanism design. The paper's first author is Ziyue Li, a Ph.D. student (class of 2021) at the Institute of Advanced Equipment Design and Control Engineering, and Professor Weizhong Guo is the corresponding author.

Due to factors such as manufacturing tolerances, assembly errors, external forces, and temperature variations, real mechanisms inevitably deviate from their ideal theoretical models. As a result, exploring efficient and robust precision solutions has become a key research focus in the field of mechanism science. In this study, the concept of Kinematic Error Node is defined and used as the fundamental unit for mechanism error analysis. A mapping model is established to describe the relationship between the error sources in kinematic pairs and components and the resulting errors at the end-effector of the mechanism.

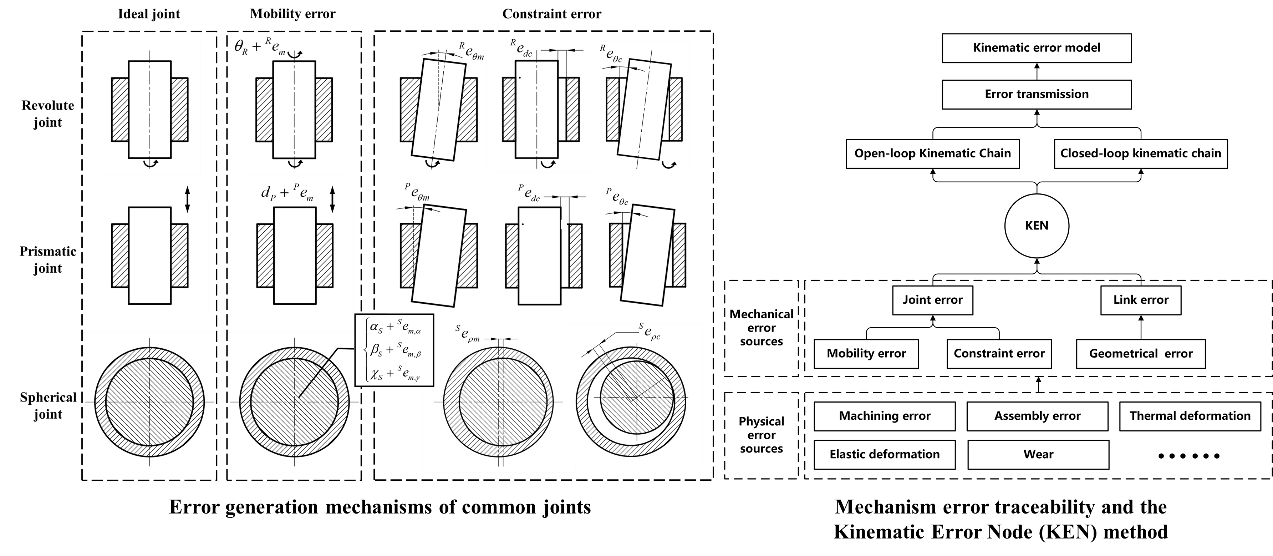

To address the problem of error traceability in mechanisms, the team conducted a systematic investigation into the mechanism of error generation from the perspective of mechanism theory. They were the first to propose that the essence of mechanism error lies in the failure of kinematic constraints. Based on the fundamental elements of mechanisms, the team categorized the error sources into three types: geometric constraint errors in kinematic pairs, geometric errors in links, and mobility errors in kinematic pairs. This classification theoretically reveals the generation and transmission mechanisms of errors in a comprehensive manner, ensuring the theoretical completeness of error sources and laying a solid foundation for complete mechanism error modeling.

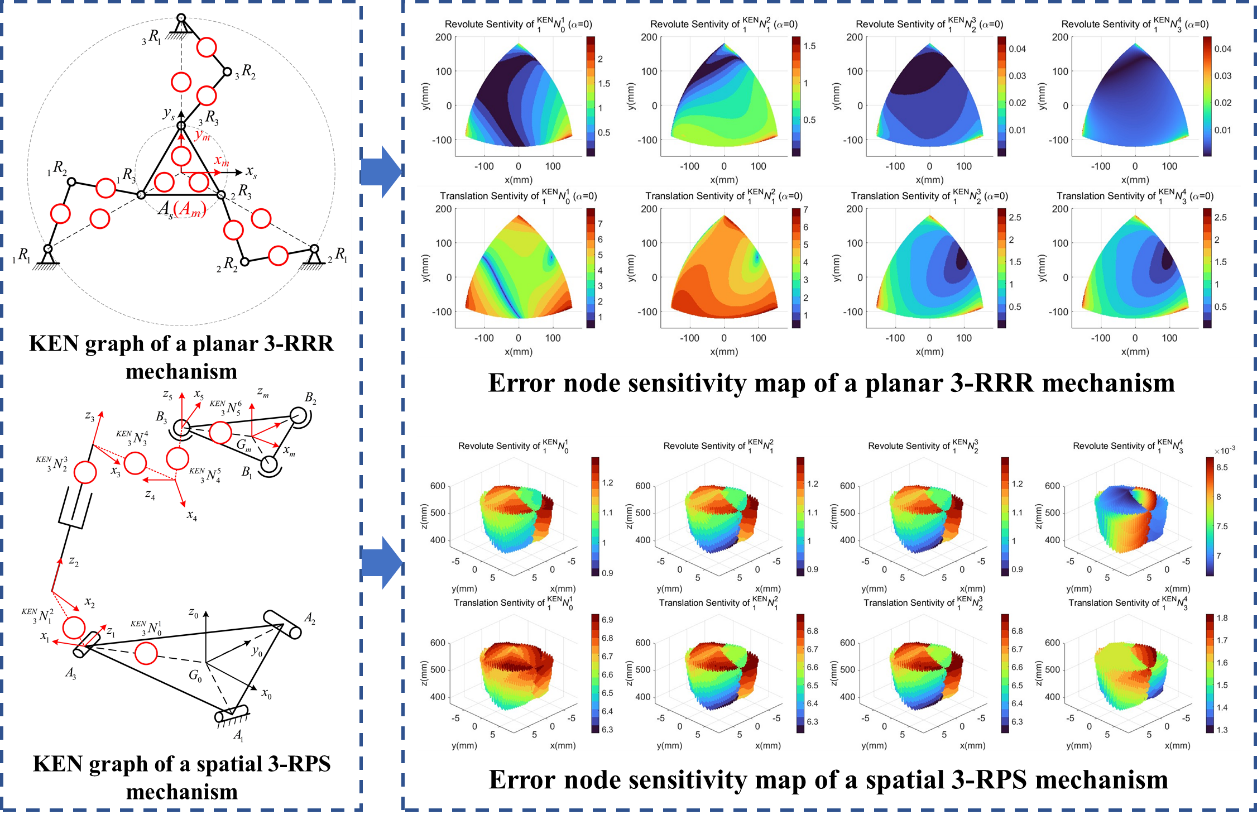

In terms of error modeling methodology, the team was the first to propose the concept of the Kinematic Error Node (KEN), treating it as the fundamental unit for mechanism error analysis. By utilizing the KEN model, the approach decouples the physical sources from the kinematic modeling framework. Based on this, the team developed a unified, general, and complete recursive error modeling method, providing a comprehensive and universal framework for precision analysis of mechanisms.

To tackle the complexity and lack of intuitiveness in conventional mechanism error modeling, the team proposed a method for drawing kinematic error node graphs. By constructing KEN graphs for both serial and parallel kinematic chains, the distribution of error sources within the mechanism can be visualized in a clear and intuitive manner, offering researchers a graphical tool for better understanding and analysis.

This paper presents a systematic study on the traceability and underlying mechanisms of mechanism errors, and is the first to achieve completeness in the parameterization of errors within error modeling. The error modeling method proposed by the research team serves as a general framework for error analysis, providing a more comprehensive and in-depth solution for the precision analysis and synthesis of modern mechanisms. It is expected to significantly advance the fields of error analysis, precision design, and performance calibration in modern mechanical systems such as robotics and intelligent equipment.

Mechanism and Machine Theory, founded in 1970, is the flagship and official research journal of the International Federation for the Promotion of Mechanism and Machine Science (IFToMM) and a top journal in the general area of mechanism and machine science. It focuses on publishing high-quality research papers in the field of mechanism and machine science and enjoys a prestigious reputation in the international community.

Professor Weizhong Guo's team is dedicated to solving fundamental scientific problems and key technologies in modern kinematics and parallel robotics. Their goal is to drive innovation in major engineering applications such as robotics and aerospace through breakthroughs in fundamental theory. In recent years, the team has published over 30 papers in journals such as Mechanism and Machine Theory, ASME Journal of Mechanisms and Robotics, ASME Journal of Mechanical Design, and IEEE Transactions on Robotics.

Paper link:https://www.sciencedirect.com/science/article/pii/S0094114X25000734

Shanghai Jiao Tong University

Address: 800 Dongchuan Road, Shanghai

200240